Width or Length Confusion: 10 Professional Secrets Finally Revealed

Picture this: You’re standing in a furniture store, measuring tape in hand, trying to figure out if that beautiful sofa will fit through your doorway. The salesperson rattles off dimensions: “32 by 84 by 36 inches.” Your mind races – which comes first width or length? This moment of confusion happens to millions of people every day, from homeowners to professionals across various industries.

Understanding dimensional order isn’t just about avoiding furniture mishaps. It’s a fundamental skill that impacts everything from construction projects to shipping packages, from interior design to engineering blueprints. The question of what goes first length or width has practical implications that can save time, money, and countless headaches.

In this comprehensive guide, we’ll break down the logic behind dimensional ordering, examine why different industries follow specific conventions, and provide you with the knowledge to confidently navigate measurements in any situation. Whether you’re a student, professional, or simply someone who wants to measure things correctly, this article will clear up the confusion once and for all.

Basic Concepts

Before we tackle the main question of width or length priority, let’s establish some foundational understanding about dimensions and measurements.

Understanding the Three Primary Dimensions

Every object in our three-dimensional world can be described using three basic measurements. These fundamental dimensions help us communicate size, shape, and spatial relationships effectively.

Length typically represents the longest horizontal measurement of an object. Think of a dining table – the length is usually the side where people sit facing each other. It’s the dimension that extends from one end to the other along the object’s primary axis.

Width generally refers to the measurement from side to side, perpendicular to the length. Using our dining table example again, the width would be the distance from the long side to the opposite long side – essentially how “wide” the table appears when you’re looking at it from the end.

Height represents the vertical measurement, showing how tall an object stands from its base to its top. This dimension is usually straightforward since it follows the natural direction of gravity.

Why Dimension Order Matters

The sequence in which we list dimensions isn’t arbitrary – it serves several important purposes. Standardized ordering prevents miscommunication, reduces errors in manufacturing and construction, and creates a universal language that professionals can rely on.

Consider the chaos that would ensue if every carpenter, architect, or manufacturer used their own preferred order for listing width or length. A simple miscommunication could result in doors that don’t fit their frames, boxes that can’t hold their intended contents, or furniture that won’t fit through doorways.

The Order of Dimensions

Standard Convention in Most Industries

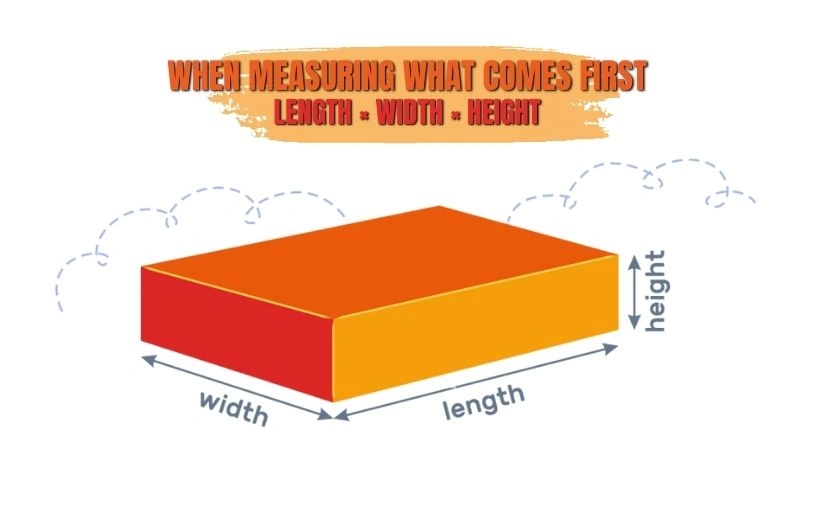

The most widely accepted convention follows the sequence: Length × Width × Height. This order has become the standard across numerous industries and applications, from furniture manufacturing to shipping logistics.

Length width height represents the traditional approach that most people learn in school and encounter in everyday situations. When you see dimensions listed as “84 × 32 × 36 inches,” you can typically assume the first number represents length, the second represents width, and the third represents height.

This convention makes sense from a practical standpoint. Length often represents the most significant or prominent dimension of an object – the measurement that gives you the best sense of the object’s overall scale and presence.

When Width Comes First

However, there are situations where width or length priority shifts, and width takes precedence. This typically happens in specific industries or when describing certain types of objects.

In textile manufacturing, for example, fabric width often comes first because it represents the standard measurement of the fabric roll. When purchasing fabric, you’ll commonly see measurements like “44-inch width” before any length specifications.

Similarly, when describing screens, displays, or windows, width might be listed first because it represents the horizontal viewing area – the dimension that most directly affects the user experience.

Geographic and Cultural Influences

Different regions and cultures have developed their own preferences for dimensions order. While the length width height sequence dominates in many Western countries, other regions might prioritize different arrangements based on their historical practices and industry standards.

European architectural drawings sometimes follow different conventions than their American counterparts, particularly when dealing with specific building components or materials. Understanding these variations becomes crucial when working on international projects or interpreting foreign documentation.

Which Comes First? A Logical Approach

The Hierarchy of Importance

When measuring what comes first often depends on which dimension carries the most significance for the specific application. This practical approach considers the primary function or most important characteristic of the object being measured.

For a bookshelf, length typically comes first because it determines how much wall space the furniture will occupy – the primary concern for most people planning their room layout. The width (or depth) comes second, as it affects how far the shelf will extend into the room.

For a picture frame, however, the approach might differ slightly. While we still generally follow length first, some people prefer to list the horizontal measurement first regardless of which is technically longer, simply because that’s how we naturally perceive rectangular images.

Functional Considerations

The question of width or length priority often resolves itself when you consider the object’s primary function. A dining table’s length matters most because it determines seating capacity. A doorway’s width might take precedence because it determines what can pass through.

Professional designers and architects have developed intuitive approaches to this decision-making process. They consider which measurement most directly impacts the object’s effectiveness, usability, or fit within its intended environment.

Industry-Specific Logic

Different industries have evolved their own logical approaches to what order are dimensions listed. These conventions weren’t developed arbitrarily – they reflect decades or centuries of practical experience and standardization efforts.

Manufacturing industries often prioritize dimensions based on production processes. If a factory primarily works with materials that come in standard widths, they might list width first to streamline their ordering and inventory systems.

Construction professionals typically follow building code conventions, which have been standardized to reduce errors and improve communication across different trades and specialties.

Cultural Variations in Dimensional Ordering

Regional Differences

While the length width height convention dominates globally, fascinating regional variations exist that reflect different cultural approaches to measurement and description.

In some Asian markets, particularly in furniture and home goods, width sometimes takes precedence over length when describing rectangular objects. This preference might stem from different cultural perspectives on how objects are perceived and utilized within living spaces.

Japanese architectural traditions, for example, have historically emphasized proportional relationships that might influence how dimensions are prioritized and communicated. These cultural nuances become important when working in international markets or collaborating across cultures.

Historical Context

The evolution of dimensional ordering reflects broader historical changes in measurement systems, industrial practices, and international commerce. Before standardization efforts, different regions, guilds, and industries maintained their own conventions for dimensions order.

The Industrial Revolution accelerated the need for standardization, as mass production and international trade required more precise and universally understood measurement conventions. The current preference for length first emerged from this period of standardization and industrial growth.

Modern Globalization Effects

Today’s interconnected economy has created pressure for universal standards, but regional preferences persist in certain industries and applications. E-commerce platforms, for example, must navigate different cultural expectations when displaying box dimensions order for international customers.

Understanding these variations becomes crucial for businesses operating globally or professionals working on international projects. What seems like a simple matter of width or length priority can have significant practical implications in cross-cultural contexts.

Practical Applications

Furniture and Home Goods

The furniture industry provides excellent examples of how dimensions order affects everyday decisions. When shopping for a sofa, the first measurement typically represents length – how much wall space the furniture will occupy along its longest side.

This convention helps consumers quickly assess whether a piece will fit their intended space. A sofa listed as “84 × 32 × 36 inches” immediately tells you that it’s 84 inches long, 32 inches deep (width), and 36 inches tall.

However, exceptions exist even within furniture categories. Platform beds might prioritize width first if they’re designed for specific mattress sizes, since the width directly corresponds to mattress dimensions (twin, full, queen, king).

Construction and Architecture

Construction professionals rely heavily on standardized dimensions order to prevent costly mistakes. Architectural drawings follow strict conventions where length width height ensures that everyone involved in a project – from architects to contractors to suppliers – interprets measurements identically.

Door and window specifications provide clear examples. A door listed as “36 × 80 inches” universally means 36 inches wide and 80 inches tall. This standardization prevents the catastrophic mistakes that could occur if different professionals interpreted these measurements differently.

Building materials also follow established conventions. Lumber dimensions, sheet materials, and other construction components use standardized ordering that reflects industry practices and manufacturing standards.

Packaging and Shipping

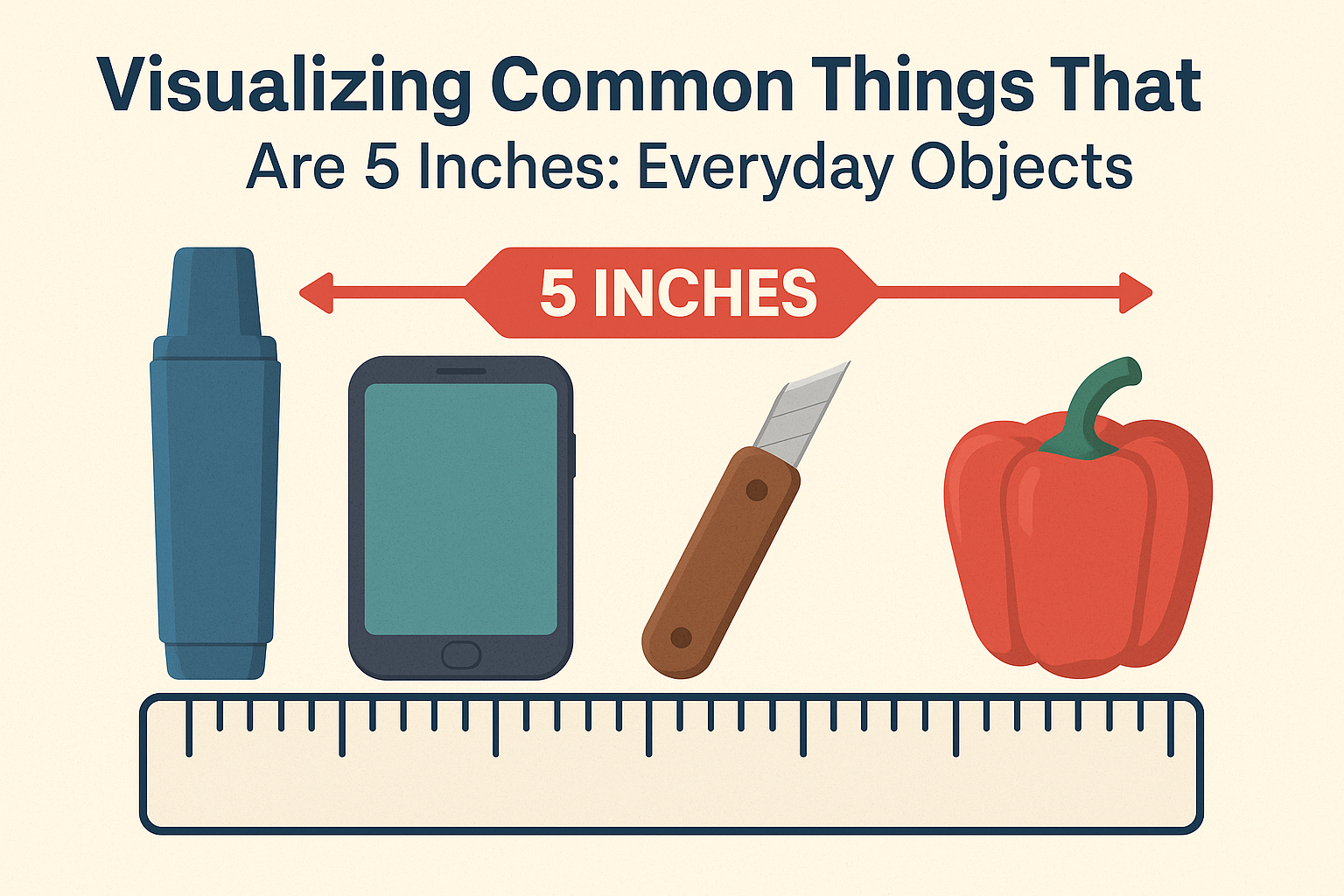

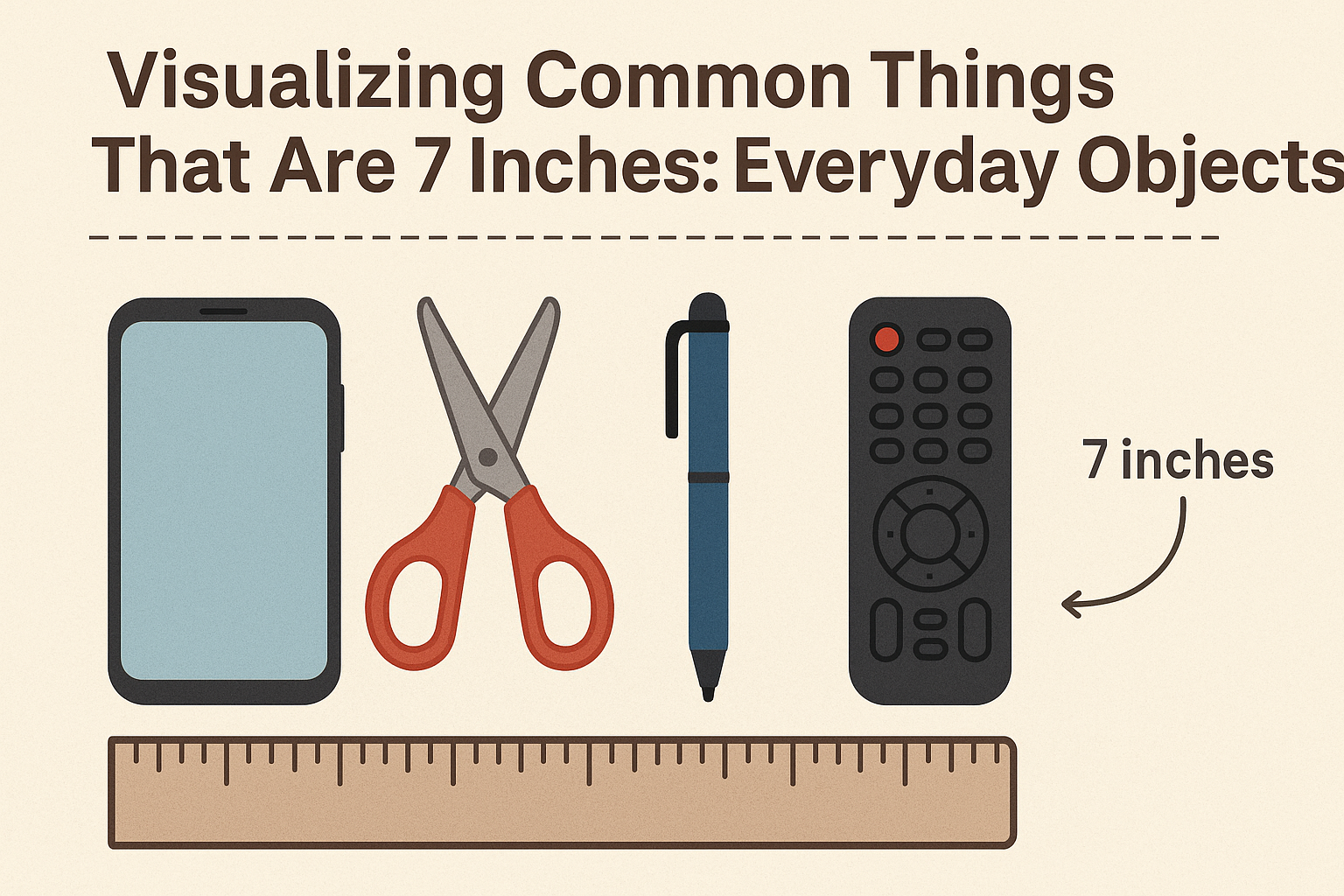

The shipping industry has developed its own approach to box dimensions order, typically following length width height but with specific considerations for handling and logistics.

Shipping boxes are often measured with length representing the longest horizontal dimension, width as the shorter horizontal dimension, and height as the vertical dimension. This convention helps warehouse workers, shipping companies, and customers understand package orientation and handling requirements.

However, some shipping companies use different conventions based on their internal systems and automation equipment. Understanding these variations becomes important for businesses that ship products regularly or consumers who frequently receive packages.

How Professionals Use Dimensions

Engineering and Manufacturing

Professional engineers and manufacturers have developed sophisticated approaches to dimensions order that reflect both technical requirements and industry standards. These professionals must consider not only measurement accuracy but also manufacturing processes, quality control, and communication efficiency.

Mechanical drawings and technical specifications follow rigorous standards for dimensional notation. The order of dimensions often reflects manufacturing sequences, assembly requirements, or functional priorities.

Quality control processes rely on consistent dimensional ordering to ensure that inspections and measurements are performed correctly and repeatably. A small confusion about width or length priority could result in defective products or failed quality standards.

Architecture and Design

Architects and designers use dimensions order as a communication tool that extends beyond simple measurement. Their dimensional notation systems convey design intent, construction sequences, and spatial relationships.

Architectural drawings include multiple types of dimensional information, from overall building dimensions to detailed component specifications. The order of these dimensions follows established conventions that ensure clear communication among all project stakeholders.

Interior designers must navigate the intersection of architectural dimensions and furniture specifications. They work with both building measurements and product dimensions, requiring fluency in multiple dimensions order conventions.

Retail and Merchandising

Retail professionals use dimensional information to optimize store layouts, manage inventory, and help customers make informed purchases. Their approach to width or length priority reflects customer needs and sales effectiveness.

Visual merchandising relies on understanding how dimensional information affects customer perception and decision-making. Display planning requires careful consideration of product dimensions and space constraints.

Inventory management systems use standardized dimensional information to optimize storage, shipping, and handling processes. Consistent dimensions order helps automated systems and human workers perform their tasks efficiently and accurately.

Length vs. Width

Defining Length in Different Contexts

Length represents different concepts depending on the context and object being measured. In most cases, length refers to the longest horizontal dimension, but exceptions exist that can create confusion.

For rectangular objects like tables or rugs, length typically means the longer of the two horizontal measurements. This definition works well for most furniture and home goods applications.

However, for objects with specific orientations or functions, length might refer to a particular dimension regardless of which is actually longer. A hallway runner rug, for example, has its length determined by the hallway’s direction, not necessarily the rug’s longest measurement.

Understanding Width Applications

Width generally represents the measurement from side to side, but like length, its specific meaning can vary with context. The key to understanding width lies in recognizing the object’s orientation and primary function.

In fabric and textile applications, width has a very specific meaning related to how the material is manufactured and sold. Fabric width represents the measurement across the bolt or roll, regardless of how the finished product will be oriented.

For vehicles, width represents the measurement from one side to the other, which is crucial for determining whether the vehicle will fit through gates, parking spaces, or garage doors.

Common Confusion Points

The most frequent confusion about length vs. width occurs with rectangular objects that don’t have obvious orientation cues. A simple rectangular table, for example, could be oriented with either dimension serving as length or width.

Professional approaches to this confusion typically rely on context clues and intended use. A dining table’s length is usually the side where people sit facing each other, regardless of which measurement is numerically larger.

Another common confusion point involves objects that can be oriented in multiple ways. A rectangular picture frame might have different length and width designations depending on whether it’s displayed in portrait or landscape orientation.

What Is Depth?

Depth vs. Width Distinction

Depth represents how far an object extends from front to back, and it’s often confused with width in dimensional discussions. Understanding this distinction is crucial for accurate measurement and communication.

In furniture applications, depth typically describes how far a piece extends into a room from the wall. A sofa’s depth determines how much floor space it will occupy, while its width determines how much wall space it needs.

Depth becomes particularly important in space planning and interior design, where understanding how far objects project into a room affects traffic flow and overall functionality.

Three-Dimensional Thinking

Depth adds the third dimension to our understanding of objects, moving beyond simple length and width to create complete spatial awareness. This three-dimensional thinking is essential for many practical applications.

Kitchen design provides excellent examples of depth considerations. Cabinet depth, appliance projections, and countertop extensions all affect how efficiently a kitchen functions and how comfortable it feels to use.

Parking and storage applications also rely heavily on depth understanding. Garage dimensions, storage unit sizes, and parking space layouts all require careful consideration of how far objects extend in three-dimensional space.

Depth vs. Height

Vertical vs. Horizontal Measurements

The distinction between depth and height represents the difference between horizontal projection and vertical measurement. Both are crucial for complete dimensional understanding, but they serve different purposes in practical applications.

Height measures vertical distance and is typically straightforward – it’s how tall something stands from bottom to top. Depth, however, measures horizontal distance in a specific direction, usually from front to back.

Understanding both measurements becomes crucial for applications like furniture placement, where you need to know both how tall something is (height) and how far it extends into the room (depth).

Practical Implications

The practical difference between depth and height affects many everyday decisions. When choosing furniture, height determines whether it will fit under low ceilings or through doorways, while depth determines whether it will fit in the available floor space.

Storage solutions require careful consideration of both dimensions. A tall, narrow bookshelf might fit in a room’s height constraints but project too far into the space for comfortable use.

Appliance installations often require balancing height and depth considerations. A refrigerator might fit the available height but extend too far into the kitchen workspace.

Depth in Different Contexts

Architectural Applications

In architectural contexts, depth often refers to how far a building element extends from a primary surface. Window depth, for example, describes how far the window assembly projects from or recesses into the wall surface.

Foundation depth represents how far below ground level the building’s support structures extend. This measurement is crucial for structural integrity and building code compliance.

Room depth describes how far a space extends from its entrance or primary opening. This measurement affects furniture arrangement, lighting requirements, and overall functionality.

Manufacturing and Industrial Uses

Manufacturing processes often use depth to describe how far tooling, materials, or components extend into or project from primary surfaces. Machining operations, for example, specify cut depth to ensure proper material removal and dimensional accuracy.

Industrial storage systems use depth measurements to optimize space utilization and ensure proper access to stored materials. Warehouse racking systems, for example, must balance storage depth with accessibility requirements.

Quality control processes in manufacturing often include depth measurements to ensure that components meet specifications and will function properly in their intended applications.

Measuring Depth

Tools and Techniques

Measuring depth accurately requires appropriate tools and techniques that differ from simple length and width measurements. Traditional measuring tapes work well for accessible depth measurements, but some situations require specialized approaches.

Depth gauges provide accurate measurements for recesses, holes, and other features where traditional measuring tools might not reach or provide accurate readings. These specialized tools ensure precise depth measurements in manufacturing and technical applications.

Digital calipers can measure depth with high precision for smaller objects and detailed work. These tools are essential for technical applications where depth accuracy affects functionality or quality.

Common Measurement Challenges

Depth measurements often present challenges that don’t occur with length and width measurements. Access limitations, angle restrictions, and reference point identification can all complicate depth measurement processes.

Furniture and appliance depth measurements require careful attention to reference points. Does the measurement include handles, hinges, or other projecting elements? Different manufacturers and retailers might use different reference standards.

Architectural depth measurements must account for various building elements and installation requirements. Wall depth might need to include finish materials, insulation, and structural components depending on the application.

Depth vs. Thickness

Material Properties

The distinction between depth and thickness relates to how we perceive and measure different types of materials and objects. Thickness typically describes the measurement through a material, while depth describes spatial projection or recession.

Sheet materials like plywood, metal plates, or glass panels are described by their thickness – the measurement through the material from one surface to the opposite surface. This measurement affects strength, weight, and application suitability.

Depth, in contrast, typically describes spatial relationships and dimensional projections. A shelf’s depth describes how far it extends from the wall, while its thickness describes the measurement through the shelf material itself.

Application Differences

Understanding when to use depth versus thickness terminology helps communicate more effectively and avoid confusion in technical and practical applications.

Construction materials are typically described by thickness when referring to their intrinsic properties and by depth when referring to their installed dimensions or spatial relationships.

Manufacturing specifications distinguish between thickness (material properties) and depth (dimensional features) to ensure clear communication and proper part functionality.

Frequently Asked Questions:

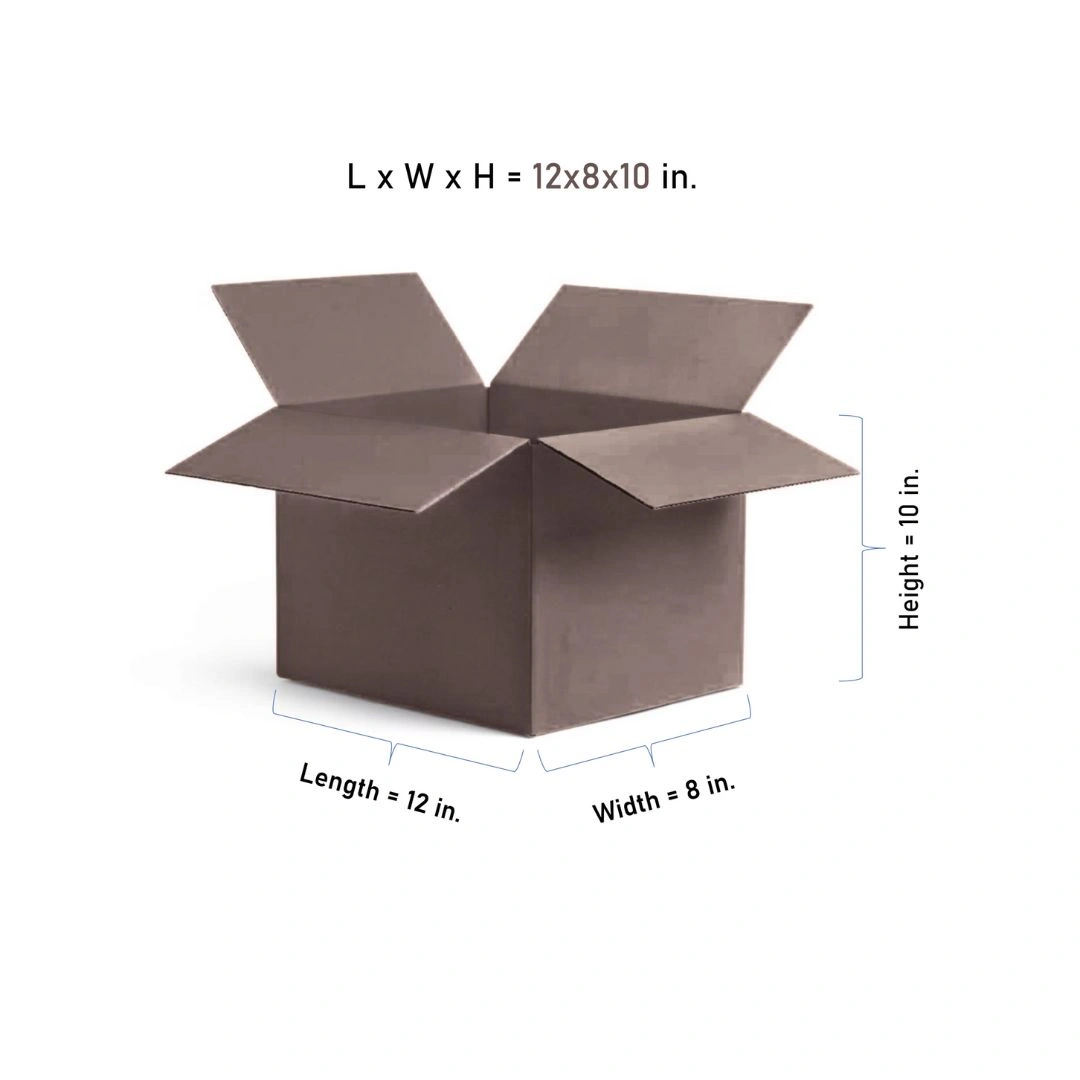

1. How Do You Read Box Dimensions Order?

A: Box dimensions typically follow Length × Width × Height format. The length is the longest horizontal side, width is the shorter horizontal side, and height is the vertical measurement. Some shipping companies may use different conventions, so always check their specific guidelines.

2. Is Width the Same as Depth?

A: No, width and depth are different measurements. Width measures from side to side, while depth measures how far an object extends from front to back. For furniture, width is the horizontal span, and depth is how far it projects into the room.

3. Why Does Dimensional Order Matter?

A: Dimensional order prevents costly mistakes in manufacturing, construction, and purchasing. Consistent width or length ordering ensures clear communication between professionals, reduces errors, and helps consumers make informed decisions about fit and space requirements.

Conclusion

Understanding the proper order of dimensions – specifically resolving the question of width or length priority – is more than just a technical detail. It’s a practical skill that affects everything from home improvement projects to professional communications across multiple industries.

The standard length width height convention provides a reliable foundation for most applications, but recognizing when exceptions apply and understanding the reasoning behind different approaches will serve you well in various situations. Whether you’re measuring furniture for your home, interpreting architectural drawings, or specifying product dimensions for your business, consistent application of dimensional ordering principles will help you communicate more effectively and avoid costly mistakes.

The key to mastering dimensional ordering lies in understanding the context, recognizing the primary function or most important characteristic of what you’re measuring, and applying industry-standard conventions where they exist. When measuring what comes first depends on practical considerations, cultural contexts, and professional standards that have evolved over time to serve specific needs and applications.

As you continue to encounter dimensional specifications in your personal and professional life, remember that the goal is clear communication and practical functionality. Whether width or length comes first in any particular situation, the important thing is consistency, accuracy, and understanding the reasoning behind the chosen approach.

For businesses and professionals seeking reliable guidance on dimensional standards and measurement best practices, Dimensions Path offers comprehensive resources and expert consultation to ensure that your dimensional specifications meet industry standards and communicate effectively with your intended audience.

🔗 Don’t miss our blog on Computer Monitor Dimensions at Dimensions Path! 🖥️

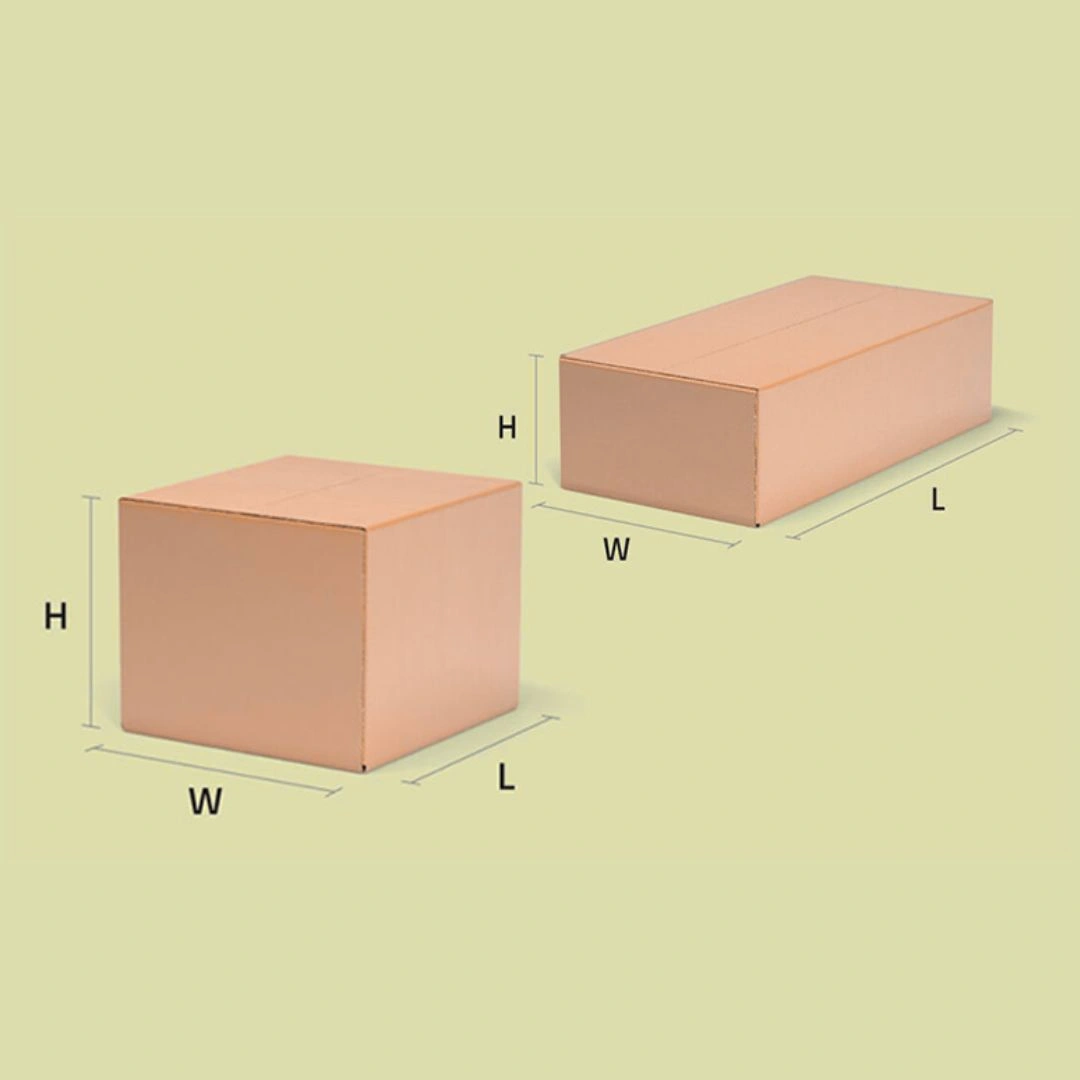

Understand Dimensions: Length × Width × Height

📌 The standard order is:

Length × Width × Height🧭 Explanation:

– Length is usually the longest side (front to back).

– Width is side-to-side (left to right).

– Height is from bottom to top (vertical).

🛠️ This order is used in shipping, packaging, construction, and eCommerce.