9 Must-Have Measurement Tools for Every DIY Project Enthusiast

Picture this: You’re halfway through building your dream bookshelf when you realize the shelves don’t fit. The wood is cut, the screws are in, but everything is just… wrong. This nightmare scenario happens to countless DIY enthusiasts every year, and it all comes down to one crucial factor: using the right Measurement Tools for DIY Projects. Whether you’re a weekend warrior tackling home improvements or a professional craftsperson, having the right measuring equipment can make the difference between success and costly mistakes.

In today’s world of precision and perfection, Measurement Tools have become more sophisticated and accessible than ever before. From traditional rulers to high-tech laser devices, these instruments serve as the foundation for every successful project. This article will walk you through the essential Measurement Tools every DIY enthusiast and professional should have, helping you choose the right equipment for your specific needs and budget.

Understanding the Importance of Accurate Measurements

Accurate measurements form the backbone of any successful project, whether you’re hanging a picture frame or constructing a deck. Poor measurements lead to wasted materials, frustrated workers, and projects that simply don’t work as intended. Measurement Tools eliminate guesswork and provide the precision needed for professional-quality results.

The cost of measurement errors extends far beyond just materials. Time spent redoing work, the frustration of failed projects, and the potential safety hazards of improperly fitted components all stem from inadequate measuring practices. Professional contractors understand that investing in quality Measurement Tools pays for itself through reduced waste and improved efficiency.

Modern Measurement Tools have evolved to address the challenges faced by both professionals and hobbyists. These tools now offer greater accuracy, easier readability, and enhanced durability compared to their predecessors. The integration of digital technology has made precise measurements more accessible to everyday users.

Traditional Measurement Tools That Never Go Out of Style

Rulers and Straight Edges

The humble ruler remains one of the most versatile Measurement Tools in any toolkit. Available in various lengths from 6 inches to several feet, rulers provide quick and accurate measurements for smaller projects. Metal rulers offer superior durability and precision compared to plastic alternatives, making them ideal for marking cut lines and checking alignments.

Architect’s rulers, also known as scale rulers, deserve special mention for their ability to work with scaled drawings and blueprints. These specialized Measuring Tools feature multiple scales on different edges, allowing users to quickly convert between different measurement ratios without complex calculations.

Tape Measures

No discussion of essential Measurement Tools can be complete without highlighting the tape measure. This portable powerhouse has been a staple in toolboxes for generations, and modern versions offer features that make them more useful than ever. Look for tape measures with magnetic tips, easy-to-read markings, and robust cases that can withstand job site conditions.

The standout distance of a tape measure refers to how far the tape can extend before it bends under its own weight. Professional-grade models can achieve standout distances of 10 feet or more, making solo measurements much easier. Some advanced models also include digital displays and memory functions for storing frequently used measurements.

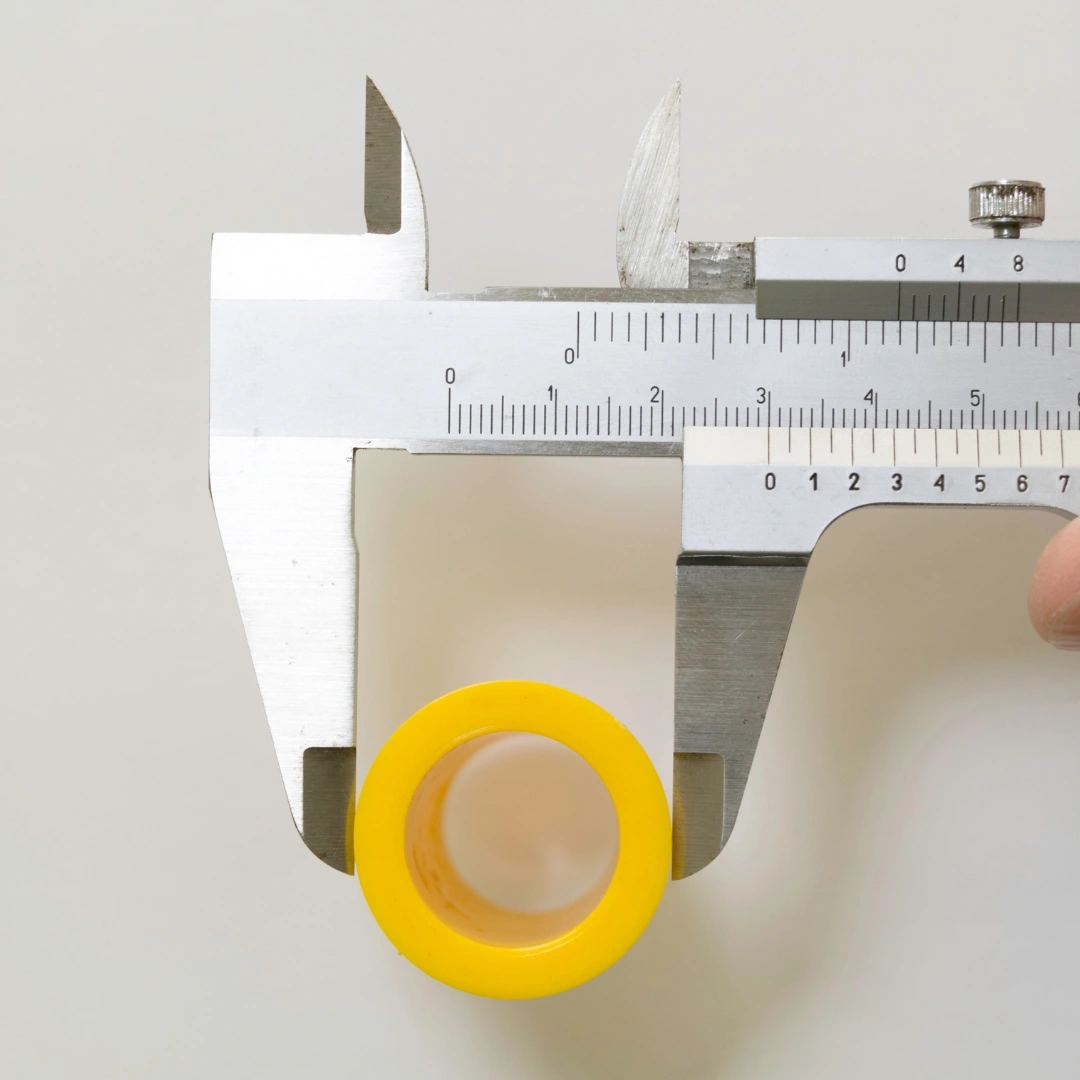

Calipers for Precision Work

When projects demand extreme precision, calipers become indispensable Tool for Measuring. These instruments can measure internal dimensions, external dimensions, and depths with remarkable accuracy, often to within thousandths of an inch. Digital calipers display measurements in both metric and imperial units, eliminating conversion errors.

Dial calipers offer a middle ground between traditional and digital models, providing precise measurements with analog displays that many craftspeople prefer. Vernier calipers, while requiring more skill to read, offer exceptional accuracy and reliability without depending on batteries or electronic components.

Leveling and Alignment Measurement Tools

Spirit Levels

A properly aligned project starts with accurate leveling, making spirit levels essential Measurement Tools for countless applications. These tools use air bubbles suspended in liquid-filled vials to indicate when surfaces are perfectly horizontal or vertical. Modern levels feature multiple vials for checking different orientations simultaneously.

Torpedo levels, compact and lightweight, excel in tight spaces where full-size levels won’t fit. Box beam levels, typically 24 to 48 inches long, provide greater accuracy over longer distances. Some premium models include digital readouts that display the exact degree of deviation from level, perfect for applications requiring specific angles.

Laser Levels

Technology has revolutionized leveling with the introduction of laser levels, sophisticated Measurement Tools that project visible light lines across work surfaces. These devices eliminate the need for chalk lines and provide reference points that remain visible throughout the project duration. Self-leveling laser levels automatically adjust for minor setup imperfections.

Cross-line laser levels project both horizontal and vertical lines simultaneously, creating perfect reference grids for tile installation, picture hanging, and cabinet mounting. Rotary laser levels sweep a continuous beam around the work area, ideal for outdoor projects and large-scale construction applications.

Advanced Digital Measurement Tools

Digital Angle Finders

Precise angle measurement becomes simple with digital angle finders, versatile Measurement Tools that display exact angles on easy-to-read screens. These tools prove invaluable for crown molding installation, roof work, and any project involving non-standard angles. Many models store angle measurements for later reference.

Magnetic bases allow digital angle finders to attach securely to metal surfaces, freeing both hands for other tasks. Some advanced models calculate complementary angles automatically, speeding up complex cutting operations and reducing the chance of mathematical errors.

Electronic Distance Measurers

Laser distance measurers represent the cutting edge of portable Measurement Tools, capable of measuring distances up to several hundred feet with remarkable accuracy. These devices project a laser beam to the target surface and calculate distance based on the time required for the beam to return.

Professional-grade laser measurers include features like area and volume calculations, continuous measurement modes, and the ability to add or subtract measurements for complex calculations. Some models connect to smartphones via Bluetooth, allowing measurements to be stored and shared digitally.

Specialized Measurement Tools for Specific Applications

Squares and Try Squares

Ensuring perpendicular angles requires dedicated Measurement Tools designed specifically for this purpose. Try squares, combination squares, and speed squares each serve different functions while maintaining the same basic principle of providing accurate 90-degree references.

Speed squares, triangular in shape, combine multiple functions in a single tool. They serve as a square, protractor, and saw guide, making them particularly popular among framers and rough carpenters. The built-in degree markings allow for quick angle measurements without separate tools.

Micrometers for Ultimate Precision

When tolerances are measured in thousandths of an inch, micrometers become essential Tool for Measuring. These precision instruments excel at measuring small dimensions with extraordinary accuracy, making them indispensable for machining and mechanical work.

Digital micrometers eliminate reading errors associated with traditional mechanical models, displaying measurements clearly on digital screens. Ratcheting mechanisms ensure consistent measuring pressure, improving accuracy and repeatability across multiple measurements.

Choosing the Right Measurement Tools for Your Needs

Consider Your Project Types

The selection of appropriate Measurement Tools depends heavily on the types of projects you typically undertake. Woodworkers need different tools than plumbers, and hobbyists have different requirements than professional contractors. Start by identifying your most common measuring tasks.

General construction work benefits from a basic set including tape measures, levels, and squares. Fine woodworking demands precision tools like calipers and micrometers. Electrical work often requires specialized measuring devices for voltage, current, and resistance measurements.

Budget Considerations

Quality Measurement Tools represent a significant investment, but they pay dividends through improved accuracy and longevity. Professional-grade tools typically offer superior accuracy, durability, and warranty support compared to budget alternatives. However, hobbyists may find that mid-range tools provide adequate performance for occasional use.

Consider the frequency of use when making purchasing decisions. Tools used daily justify higher prices, while occasionally used items might warrant more economical choices. Many professionals recommend starting with quality basics and upgrading specialized tools as needs become apparent.

Accuracy Requirements

Different projects demand different levels of precision from Measurement Tools. Rough framing work might tolerate measurements accurate to 1/8 inch, while furniture making often requires precision to 1/32 inch or better. Understanding your accuracy requirements helps narrow tool selections significantly.

Digital tools generally offer superior accuracy compared to analog alternatives, but they require batteries and may be more susceptible to damage in harsh environments. Mechanical tools provide reliable performance regardless of conditions but may require more skill to read accurately.

Maintenance and Care of Measurement Tools

Proper Storage Practices

Protecting your investment in quality Measurement Tools requires appropriate storage and handling practices. Moisture, temperature extremes, and physical damage all contribute to decreased accuracy and shortened tool life. Dedicated tool storage systems keep instruments organized and protected.

Tape measures benefit from being stored in their retracted position to prevent spring fatigue. Levels should be stored horizontally to prevent bubble shifting. Precision instruments like calipers and micrometers require protective cases to prevent damage to delicate measuring surfaces.

Regular Calibration

Maintaining accuracy requires periodic calibration of Measurement Tools, particularly digital instruments and precision devices. Many professional tools include calibration certificates indicating their accuracy at the time of manufacture. Regular checking against known standards ensures continued precision.

Simple calibration checks can be performed using certified reference standards or by comparing multiple tools of the same type. Professional calibration services provide traceable accuracy certifications required for quality control applications and critical measurements.

Cleaning and Protection

Proper cleaning extends the life of Measurement Tools while maintaining their accuracy. Dust, debris, and corrosion all contribute to measurement errors and mechanical problems. Use appropriate cleaning methods for different tool types and materials.

Metal tools benefit from light oil applications to prevent rust and corrosion. Digital instruments require careful cleaning around displays and electronic components. Avoid harsh chemicals that might damage markings or electronic components in modern Measuring Tools.

Safety Considerations When Using Measurement Tools

Laser Safety

Laser-equipped Measurement Tools require special safety considerations to prevent eye damage and other injuries. Never look directly into laser beams, and be aware of reflective surfaces that might redirect beams unexpectedly. Follow manufacturer safety guidelines and consider using laser safety glasses in bright environments.

Class II lasers, common in consumer measuring tools, are generally safe for incidental exposure but should not be viewed directly. Class III lasers, found in some professional equipment, require additional safety precautions and may be regulated in certain jurisdictions.

Electrical Safety

Digital Measurement Tools that measure electrical properties require additional safety awareness. Ensure tools are rated for the voltages and currents being measured, and follow proper lockout procedures when working on electrical systems. Damaged test leads pose serious safety hazards.

Regular inspection of electrical measuring equipment prevents accidents and ensures accurate readings. Look for damaged insulation, bent probes, and cracked displays that might compromise safety or accuracy. Replace damaged equipment immediately rather than attempting repairs.

Future Trends in Measurement Tools

Smart Technology Integration

The integration of smartphone technology with traditional Measurement Tools opens new possibilities for measurement, recording, and sharing project data. Apps can store measurements, calculate materials, and even generate cutting lists automatically. Bluetooth connectivity allows tools to communicate directly with mobile devices.

Augmented reality applications overlay measurement information onto real-world views through smartphone cameras, helping visualize projects before construction begins. These technologies make complex measurements more accessible to occasional users while providing new capabilities for professionals.

Improved Accuracy and Ease of Use

Manufacturers continue advancing Measurement Tools with improved accuracy, durability, and user-friendly features. Voice activation, larger displays, and simplified controls make tools more accessible to users with different abilities and experience levels.

Automated measurement recording eliminates transcription errors while creating permanent records of project dimensions. These features prove particularly valuable for complex projects requiring multiple measurements and calculations.

Building Your Measurement Tools Collection

Essential Starting Kit

New DIY enthusiasts and professionals should start with a core collection of versatile Measurement Tools that handle the majority of common measuring tasks. A quality tape measure, 2-foot level, combination square, and basic ruler form the foundation of any measuring toolkit.

This basic kit handles most home improvement projects and light construction work. As experience and project complexity increase, additional specialized tools can be added based on specific needs and preferences.

Expanding for Specialized Work

Different trades and hobbies require specialized Measurement Tools beyond the basic kit. Electricians need multimeters and voltage testers, while woodworkers benefit from precision squares and marking gauges. Plumbers require levels designed for pipe installation and water flow considerations.

Research the specific requirements of your intended projects before investing in specialized equipment. Online forums, trade publications, and professional advice help identify the most useful tools for specific applications.

Common Mistakes to Avoid

-

Ignoring tool accuracy: Cheap or old Measurement Tools may give false readings.

-

Not marking properly: Always use a marking tool to transfer your measurements.

-

Forgetting to account for tool thickness: Some Measuring Tools have a physical width that can affect your final result.

-

Skipping calibration: Especially with digital Measurement Tools, regular calibration is a must.

Conclusion

No matter your skill level, the right Measurement Tools are the foundation of every successful DIY project. They ensure your work is accurate, efficient, and professional-looking. Whether you’re building a deck, crafting furniture, or just hanging a picture, investing in reliable Measurement Tools pays off every time.

If you’re ready to take your projects to the next level, make sure your toolkit is stocked with the best Measurement Tools. For quality, variety, and expert advice, trust dimensions path to help you measure up to your ambitions.

Frequently Asked Questions: Measurement Tools

1. What are the most essential Measurement Tools for beginners?

A. The most essential Measurement Tools for beginners include a tape measure, steel ruler, spirit level, and a square. These tools cover most basic measuring needs in DIY projects.

2. How do I choose the right Measurement Tool for my project?

A. Consider the type of material, the level of precision required, and the size of your project. For example, use calipers for small, detailed work and a measuring wheel for long distances.

3. Are digital Measurement Tools better than manual ones?

A. Digital Measurement Tools offer greater precision and convenience, but manual tools are often more affordable and reliable for simple tasks.

👉 Also, check out our latest guide on Chip Bag Sizes only at dimensions path!

Looking to make someone smile? Find thoughtful wishes at “TerrificWishes.com”